Search “residential concrete wall panels” and you’ll get confused. Fast.

Total building product identity crisis. The term covers two completely different products that only share the word “concrete.” On one side you’ve got heavy-duty structural precast panels – those 200kg-per-square-metre monsters that form the actual bones of buildings. On the other, lightweight decorative panels that weigh less than your average suitcase and go up over existing walls in a weekend.

This article focuses entirely on the second type. Decorative concrete panels for homes. The kind that create stunning feature walls without needing cranes or structural engineers or council approval processes that drag on for months. Because structural precast panels? About as relevant to typical home renovations as earthmoving equipment.

The concrete look has blown up in Australian residential design over the past few years. Started in architect-designed homes, filtered down to regular renovation projects where homeowners want that raw industrial edge without the construction nightmare that real poured concrete brings. And the technology finally caught up to make it actually possible.

Table of Contents

- What Are Decorative Concrete Wall Panels?

- The Real Benefits of Lightweight Concrete Cladding

- Types of Decorative Concrete Panels

- Design Applications: Where These Panels Actually Work

- Installation Realities

- Selecting Panels: Critical Decisions

- Why Choose Stonini

- Conclusion: The Real Bottom Line

What Are Residential Decorative Concrete Wall Panels? (And What They Definitely Aren’t)

Decorative concrete wall panels are lightweight cladding products that look like architectural concrete. They’re finishing materials, not structural elements. Installing them won’t help your house stand up. But they’ll definitely help it stand out.

This distinction matters because even building professionals sometimes mix up the two categories. Structural precast panels form the bones of buildings. Decorative panels provide the skin. One requires engineers and cranes. The other requires adhesive and a weekend.

These panels use glass fibre reinforced concrete (GFRC) or advanced polymer composites. The material science gets complex but here’s what matters: they capture concrete’s visual look and texture while weighing just 14-15kg per square metre instead of 200kg. Not a small improvement. Total game-changer that opens up possibilities you’d never get with traditional concrete.

The lightweight advantage means your existing walls can handle them without any reinforcement. No structural modifications. No engineering reports. No awkward conversations with building surveyors about load calculations. For apartment dwellers, heritage home owners, or anyone with lightweight construction, this changes “impossible” into “doable.”

The Real Benefits of Lightweight Concrete Cladding

Visual Impact Without the Compromises

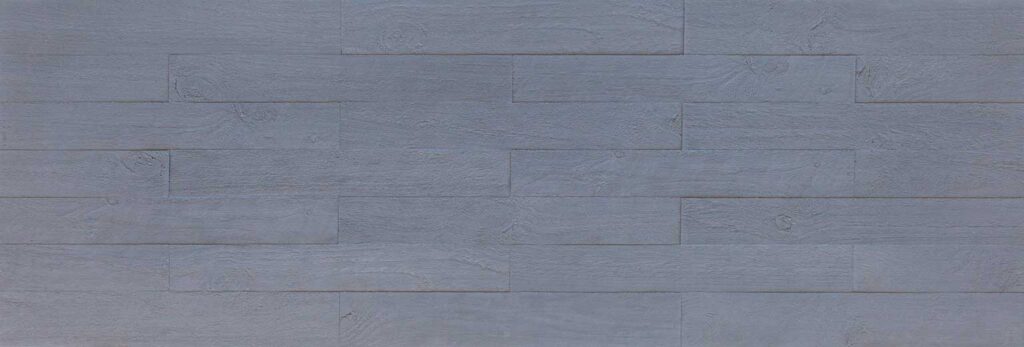

Quality faux concrete panels deliver genuine texture. Run your hand across a well-made panel and you’ll feel the surface variations, the subtle imperfections, the honest texture that makes concrete compelling. Cheap alternatives? They feel like exactly what they are. Plastic pretending to be something it’s not.

The range runs from brutally raw board-formed textures through to polished sophistication. Three-dimensional patterns create real shadow play throughout the day as natural light shifts. Custom finishes let you get exactly the concrete look your project needs rather than forcing you into three standard options.

Installation That Actually Makes Sense

Think about installing traditional concrete: you’ve got to build formwork, order the truck, coordinate the pour, wait days for it to cure, deal with waterproofing… the finishing work alone can drag on forever.

Residential Panel installation? Surface prep, adhesive, panels on, finish the joints. Done.

Most decorative panels fix straight onto plasterboard, brick or rendered surfaces using construction adhesive and mechanical fasteners. The substrate just needs to be reasonably flat and stable. Requirements most Australian homes already meet. No special mounting systems. No cavity framing. No coordinating multiple trades who all hate each other.

The speed matters beyond just convenience. Renovations disrupt life. Every extra week means another week of dust and noise and contractors showing up at dawn. Panel installations finish in single days where traditional concrete work stretches across weeks. That’s the difference between a manageable disruption and wanting to move out temporarily.

Durability That’s Worth the Money

Let’s face it, Australian weather is brutal on materials. We get UV exposure that fries most things, crazy temperature swings and weather that seems designed to break stuff. Quality interior concrete panels handle this because they’re built for it.

Fire resistance? It’s not just a checkbox. If you’re near bushfire zones or installing around a fireplace, this actually matters. Surface treatments can peel off under heat. With proper panels the concrete look goes all the way through. This isn’t marketing fluff – it’s actual performance data that matters when council requirements or insurance come into play.

Maintenance barely registers as a consideration. An occasional wipe-down removes dust. That’s it. Compare this to painted surfaces needing a refresh every few years or wallpapers that show wear at high-traffic corners. The long-term economics favour panels once you factor in decades of doing basically nothing.

Types of Decorative Concrete Panels: What’s Actually Available

Finish and Texture Options

Smooth polished finishes are all about that clean modern look. They feel more sophisticated than industrial and work perfectly in contemporary homes with minimalist designs. The reflectivity adds subtle light play, catching and bouncing natural light throughout the day. These work particularly well in schemes where texture comes from furniture and fabrics rather than the walls.

Textured and raw finishes deliver that honest unfinished look everyone’s after. Board-formed options capture every timber grain impression. Surfaces that look like formwork just came away yesterday. The texture depth varies from subtle grain patterns to pronounced relief that creates real shadow lines. These finishes work best in schemes that mix industrial edges with warmer elements.

Three-dimensional, fluted and corrugated designs are for when you want real eye-catching drama. Vertical fluting creates height and rhythm, particularly effective in rooms with good ceiling clearance. Horizontal elements add width and guide your eye across walls. The shadow patterns these create throughout the day provide visual interest without any artificial help. Just concrete and daylight doing their thing.

Exposed aggregate finishes show off the small stones and particles inside the concrete, giving it a raw organic texture that never repeats. These work exceptionally well in casual spaces. Alfresco areas, outdoor entertaining zones, relaxed living spaces where polished restraint would feel wrong.

Material Quality: What You’re Actually Getting

Look, you get what you pay for with these panels.

The cheap concrete-look stuff? It’s basically fancy wallpaper. Laminates and rigid panels that photograph okay under careful lighting but fail the touch test within seconds. Any visitor who’s ever seen real concrete knows immediately. Surface-only finishes mean the slightest damage reveals cheap substrate underneath. Try explaining to guests why your “concrete” feature wall bleeds particle board. That gets old fast. They work for temporary rental situations where authenticity doesn’t matter but using them in permanent homes? You’re setting yourself up for years of regret.

Fibre cement sheets are better but still have issues. Heavy at 15-20kg per square metre, brittle (one wrong tap and you’re buying replacement sheets) and cutting them generates silica dust clouds you don’t want to breathe. They work for basic exterior cladding where nobody touches them but calling them a residential interior solution? That’s stretching it.

The good stuff – GFRC or polymer composites – is what you actually want. This is what the category should have been delivering years ago. Real concrete appearance and texture at weights (14-15kg per square metre) that don’t need structural consultations. Weighs about as much as a couple of bags of potting mix per panel but looks and feels like real concrete. The flexibility prevents stress cracking that kills rigid alternatives. Through-body finishing means surface damage doesn’t expose different materials underneath. Manufacturing precision delivers complex shapes and fine detail that poured concrete can only dream about.

Stonini’s fiber reinforced panels sit firmly in this premium category. They combine authentic appearance with installation practicality that traditional materials simply can’t match. The manufacturing process captures textural details at scales traditional casting struggles with while the lightweight spec eliminates structural concerns that often kill concrete aesthetic plans before they start.

Design Applications: Where These Panels Actually Work

Living Spaces That Grab Attention

Living room feature walls work best opposite your main seating. Don’t overthink it – put the concrete where people naturally look when they sit down. It becomes a conversation piece without trying too hard. The textural depth works particularly well against window walls. Morning light grazing across the surface creates shadow play that shifts throughout the day. Painted walls just can’t deliver that.

Fireplace surrounds? This might be the perfect concrete panel application. The material’s fire resistance makes practical sense while the aesthetic gives living spaces the weight they deserve. Traditional brick surrounds feel dated. Painted plasterboard feels temporary. Concrete feels permanent, substantial, like it belongs exactly where it sits.

The styling needs deliberate contrast. Heavy concrete textures need softening through textiles. Wool rugs with good pile, linen throws in warm tones, leather seating that develops character. Timber furniture with visible grain provides organic balance against concrete’s manufactured look. The contrast works because it feels intentional.

Bedrooms: Making Industrial Feel Intimate

Concrete in bedrooms sounds wrong until you see it done right. The trick? Restraint and strategic positioning. A single feature wall behind the bed creates dramatic height without overwhelming the space’s intimacy. Position it correctly and it becomes an architectural statement rather than a cold industrial intrusion.

Balance is everything here. Concrete provides vertical drama and texture. Everything else provides warmth and comfort. Floating timber bedside tables soften the industrial edge. Layered textiles – multiple pillows, throws with varied textures, natural fibre underlays – create cozy contradiction against the raw concrete backdrop. Ambient lighting from wall sconces positioned to graze the concrete surface highlights texture while keeping bedroom intimacy.

Here’s an idea worth considering: rather than traditional upholstered headboards, concrete panels with integrated LED strip lighting create floating illumination effects. The light washes up the concrete texture creating gentle ambient glow that’s perfect for reading without harsh overhead glare. This changes what could feel cold into something genuinely sophisticated.

Home Offices: Professional Credibility When Zoom Matters

We all care about our Zoom backgrounds now, right? Concrete panels look professional and intentional. They don’t look like a last-minute default-builder paint job. They show you actually thought about the space.

The practical benefits go beyond appearance. Textured concrete surfaces help control acoustics in ways smooth walls don’t. Sound waves scatter rather than bouncing straight back, reducing the echo that makes small offices sound like empty chambers. This matters during calls when audio quality directly affects how professional you seem.

Built-in elements work beautifully against concrete. Floating timber desks against concrete walls create that raw-meets-refined look everyone’s after. The contrast between organic timber grain and manufactured concrete texture provides visual interest without needing artwork or decoration. Add integrated shelving in matching timber and the office becomes a complete statement.

Plus, the way natural light hits the texture changes all day. It’s a small thing but it keeps the space from feeling static and boring.

Entertainment Spaces: Beyond Red Velvet and Black Paint

Media rooms have moved past that red-velvet-and-black-paint aesthetic. Contemporary entertainment spaces need sophistication that works for family movie nights and dinner party overflows. Concrete panels deliver exactly this versatility.

The acoustic benefits aren’t marketing invention. Textured surfaces genuinely help manage sound reflections. While they won’t replace dedicated acoustic treatment in serious home theatres, they significantly improve sound quality in multi-purpose entertainment zones. The texture breaks up harsh reflections that make every sound feel like it’s echoing off tiles.

Lighting becomes critical in entertainment spaces. These rooms already have substantial lighting infrastructure for screens and general illumination. That same lighting creates dramatic effects when it grazes concrete walls. Spotlights positioned to rake across textured surfaces at low angles create shadow depth that reads differently from every viewing position. The walls become dynamic rather than static.

The material choice signals intention. This isn’t another suburban media room with predictable finishes. This is considered design where every surface serves a purpose. Visitors notice. They always notice.

Installation Realities: Why Professional Help Usually Makes Sense

The lightweight spec creates an illusion that installation is simple. While the panels themselves handle easily, getting flawless results needs carpentry skills that most keen DIYers just don’t have. This is one of those rare situations where honest assessment of your capabilities saves money, time and ultimate satisfaction.

The Professional Installation Process

Surface prep matters more than you’d think. The substrate needs proper flatness – not perfection but within reasonable tolerance. Existing walls with significant irregularities need leveling before panels proceed. This might mean additional plasterboard over stud framing, render coat application or in extreme cases complete wall reconstruction. Skip this prep and you’re guaranteed visible lippage where panels meet. Guaranteed.

Measuring and cutting demand precision woodworking capabilities. The panels cut cleanly with standard circular saws and carbide blades but getting square cuts that fit tightly needs experience beyond weekend warrior level. Internal corners need perfect miters. External corners demand precise angles. Door and window reveals need exact measurements and confident cutting. This is where DIY ambitions crash into reality.

Adhesion systems combine construction adhesive with mechanical fasteners. The adhesive provides primary fixing spreading load across panel backs. Fasteners provide temporary holding while adhesive cures and serve as backup fixing. Proper fastener selection matters – different wall substrates need different fixing types. Plasterboard needs appropriate anchors. Brick needs masonry fixings. Get this wrong and panels fall off walls which somewhat defeats the purpose.

Finishing separates adequate installations from excellent ones. Panel joints need careful treatment. Some applications leave them exposed as intentional design elements, others fill and finish them flush. The decision depends on overall aesthetic intent but execution needs patience and skill. Corner treatments demand particular attention because errors show prominently at sight lines people naturally follow.

Sealing provides final protection particularly for external applications or areas exposed to moisture. The sealer selection needs matching to specific panel material and application requirements. Not all sealers suit all panels. Professional installers understand these compatibilities. DIY enthusiasts discover them through expensive mistakes.

So… Can You Actually DIY This?

Look, technically yes. But should you? Probably not.

Unless you’re a chippie by trade or you just enjoy learning lessons the hard (and expensive) way, it’s a risky bet. Small geometrically simple projects – single feature walls in square rooms without complicated cuts – might survive keen DIYer treatment. Anything beyond that? You’re gambling expensive materials against skills you probably don’t have. Larger installations with multiple corners, intricate cuts around doors and windows or complex pattern alignments quickly exceed YouTube tutorial territory. The materials cost too much and sit too prominently to treat as practice runs.

The tool requirements look deceptively modest. Circular saw, level, adhesive gun, drill. Equipment most keen DIYers already own. But owning tools has basically nothing to do with using them well. Cutting panels consistently square demands saw technique developed across years not weekends. Getting properly level installations needs understanding how actual buildings work which often means accepting that “level” and “matching existing wonky walls” directly contradict each other.

Time investment? Take your estimate, triple it, then add a weekend. Professional installers knock out typical residential concrete feature walls in single days because they’ve done it hundreds of times. Your first attempt will stretch across multiple weekends while you discover why professionals charge what they do. The opportunity cost compounds when gorgeous spring weather goes unused because you’re crouched in your lounge wrestling panels that refuse to align.

For most residential applications professional installation is the smart investment. The cost difference between supply-only and supply-and-install runs 40-60% additional. That premium buys execution certainty, time savings and confidence that results match expectations. When materials alone cost thousands, adding professional installation for total project security makes compelling economic sense.

Selecting Panels: Critical Decisions That Matter

Application Drives What You Need

Internal versus external fundamentally determines suitable options. Internal panels need good looks and reasonable durability against casual contact and cleaning. External panels need weather resistance, UV stability and structural capacity to handle thermal cycling and moisture exposure. Using internal-rated panels externally guarantees disappointing outcomes.

Wet area applications demand extra scrutiny. While quality residential concrete panels resist casual moisture exposure adequately, prolonged water contact needs explicit wet-area rating. Bathroom applications near showers need proper waterproofing systems behind panels – the panels themselves don’t provide moisture barriers. Kitchen splashback applications work beautifully but need appropriate sealing to handle cooking splatter and cleaning chemical exposure.

The aesthetic vision determines texture and finish selection. Raw industrial looks demand board-formed or heavily textured options. Contemporary minimalism needs smooth or subtly textured surfaces. Three-dimensional designs work magnificently in feature wall applications but might overwhelm smaller rooms or entire-room coverage. Matching aesthetic intensity to space scale prevents expensive overreach.

The Non-Negotiable Sample Step

It can’t be stressed enough: NEVER specify panels without seeing and touching a physical sample. Don’t trust the photos. The colour on your phone is not the real colour and you just can’t see or feel real texture on a screen.

Proper samples arrive in sizes that actually matter for evaluation. Minimum 100x100mm, ideally larger. Those tiny sample chips showing postage-stamp views? Useless for genuine assessment. They tell you basically nothing about how the full-scale installation will read. Demand proper sample sizes or walk away.

View samples under your actual lighting conditions. That means bringing them into your actual space, not judging them under showroom spotlights or outdoor midday sun. That texture looking dramatic under grazing halogen light might disappear completely under your ceiling’s LED downlights. Natural light from your windows creates entirely different effects than artificial sources. Testing reveals these realities before commitment becomes expensive and irreversible.

Compare samples directly against your other materials. That concrete panel might look incredible alone but clash horrifically with your chosen timber flooring. Or perhaps the combination creates exactly the raw-meets-refined contrast your design needs. These critical relationships only reveal themselves through physical side-by-side comparison in actual conditions. Skip this step and you’re gambling thousands on digital representations that have questionable relationship to reality.

Why Stonini Delivers What Others Promise

Why do people pick Stonini? Three main reasons.

First, it’s made here in Australia. That’s not just flag-waving – it means you get realistic lead times measured in weeks not months. You can talk to support staff in your own time zone who actually understand local building codes and conditions. When something comes up during installation (and something always comes up) you’re talking to people who’ve dealt with identical situations hundreds of times. Not reading from a script in another country.

Second, the panels are handcrafted. That sounds fancy but what it actually means is you get subtle variations that make concrete feel authentic instead of the perfectly uniform obviously fake finish that mass-production gives you. A perfect machine-made finish just looks fake. This “controlled variation” is what you want. That hands-on approach also allows for real customisation not just picking from a catalogue. You can get custom colours or unusual panel dimensions matched to your specific project.

Third, the weight. At 14-15kg per panel you can install on standard walls. No structural engineer needed. That’s the difference between a project that actually happens versus one that dies in the “too hard” basket. This lightweight spec turns “impossible without major structural work” into “get it done this weekend” projects.

You can verify all of this just by getting a physical sample. The texture you feel on the sample is exactly what you get on the wall. The colour you see is the colour you get. This eliminates any nasty surprises when the actual panels arrive. Talk to any installer who’s worked with multiple brands and they’ll tell you – consistency matters. Stonini delivers it.

The Real Bottom Line

Here’s the real bottom line: quality really matters here. The price difference between a “meh” panel and a great one might be 30-40%. But the performance gap is decades. The math is pretty simple.

The lightweight concrete panel category crossed from “interesting alternative” to “only sensible option” somewhere around 2020. Projects that once needed six-figure budgets and structural engineering consultations now finish over single weekends. This new tech fixed all the problems of old-school concrete but kept the awesome look. You don’t have to worry about the weight, the installation is straightforward and your timeline won’t blow out.

For homeowners wanting the concrete look without the concrete headaches, quality lightweight panels are the only rational choice. Not a compromise. Not a cost-cutting workaround. Just better technology delivering the same visual results through better means.

This isn’t a fantasy spec from a magazine. It’s happening in regular homes across Australia right now. People are getting the high-end concrete look but without the cost, headache and drama that used to come with it. Suburban homes. Real renovations. People who wanted the look but not the construction nightmare.

The best way to see the difference is to get a sample. Request one from Stonini. Feel the texture yourself. See the real colour in your own home. You’ll quickly understand why settling for photos is a mistake. Because your home deserves materials that actually deliver rather than just promise.