Here’s a scenario every commercial designer knows too well: the client wants the gravitas of raw concrete in their lobby, the architect’s sketched something genuinely beautiful, and then the structural engineer kills the dream. The existing slab can’t handle it. Budget blown on remediation before a single panel goes up.

This is the reality of commercial interior specification in Australia. And it’s precisely why the term “lightweight” has become loaded—sometimes a selling point, other times a red flag for materials that compromise on fire safety or durability the moment you read the fine print.

So let’s cut through it. What actually matters when specifying lightweight wall panels for commercial interiors? And where do the genuinely engineered solutions sit against the cheap knockoffs flooding the market?

In this guide:

Performance Comparison: Weight vs. Fire Rating vs. Aesthetics

The Material Science of Engineered Lightweights

Fire Safety and NCC Compliance

Large Format Panels: Reducing Site Complexity

Aesthetic Versatility of Lightweight Wall Panels

Technical Comparison: Performance Versus Aesthetic Value

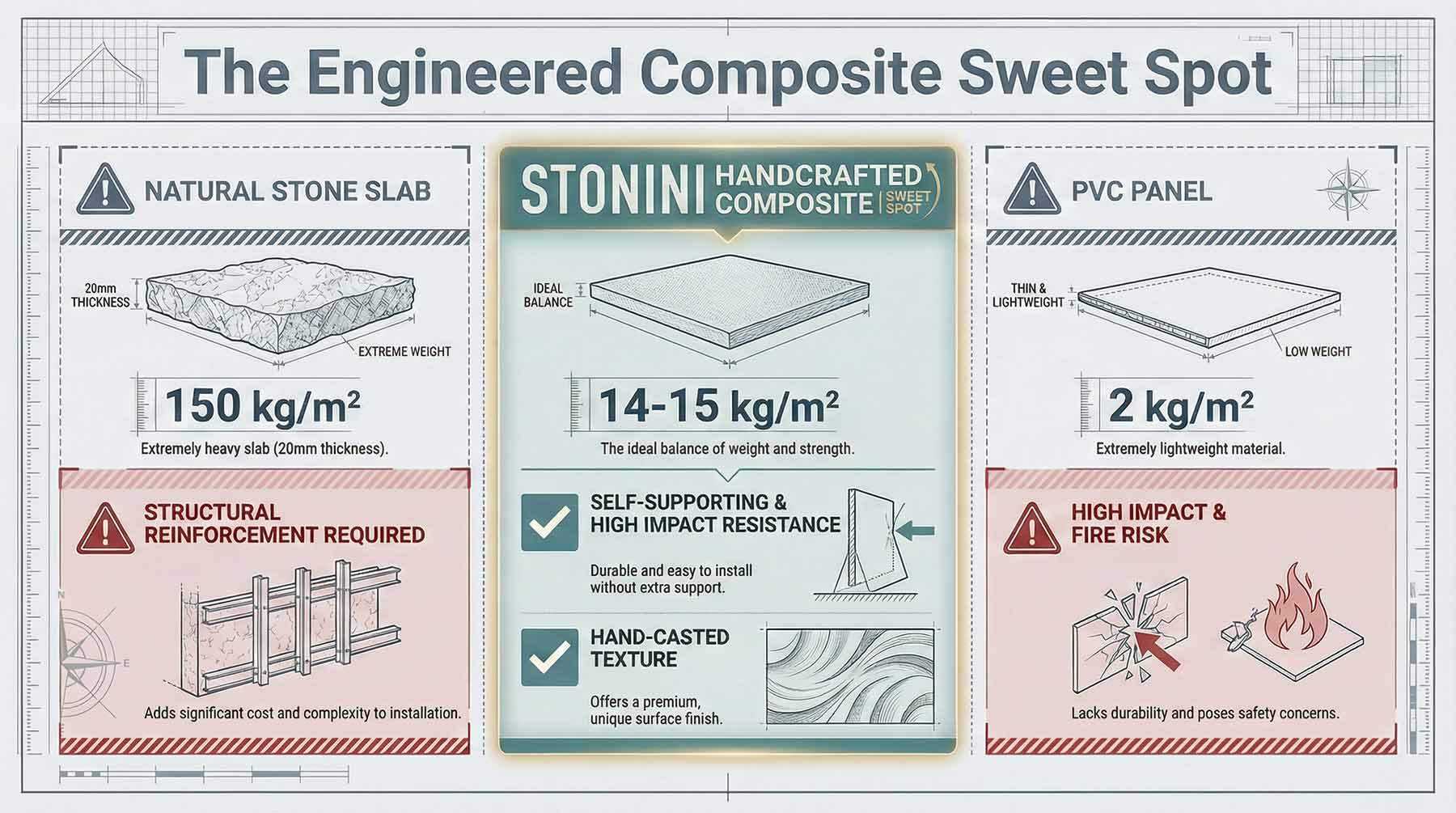

When specifying wall linings for commercial interiors, that “lightweight” label can be properly misleading. A material that’s too light often lacks the fire rating or impact resistance required for high-traffic zones, while traditional materials like stone are frequently too heavy for non-structural retrofits. You’re caught between inadequate and impossible.

Here’s how the main material categories actually stack up:

| Performance Criteria | Handcrafted wall panels (Stonini) | Wood Fibre / MDF | Polymer / PVC | Real Stone / Concrete |

|---|---|---|---|---|

| Typical Weight | 14–15 kg/m² | 8–10 kg/m² | 2–4 kg/m² | 50–150 kg/m² |

| Fire Performance (AU) | Group 1 (AS/NZS 3837) | Group 3 (Typical) | High Smoke/Combustible | Non-combustible |

| Moisture Resistance | Waterproof & Mould Resistant | Swells/Warps | Waterproof | Porous (Requires Sealing) |

| Aesthetic Authenticity | Hand-casted; No pattern repeat | Printed/Uniform | Moulded/Uniform | Natural variation |

| Installation Method | Adhesive Fix; Standard Tools | Pin/Adhesive | Adhesive | Mechanical Fix/Masonry Tools |

| Impact Resistance | High (Fibre-reinforced) | Medium | Low (Prone to cracking) | High (But brittle) |

| Sustainability (AU) | Low VOC; Australian Made | Formaldehyde risks | High Carbon Footprint | High Transport Emissions |

The numbers tell a clear story. Real stone and concrete deliver unquestionable authenticity but at weights that demand structural engineering sign-off—often $15,000+ in consulting fees alone for a lobby retrofit. PVC panels are featherweight but fail fire compliance in most commercial applications and crack if someone leans a trolley against them. MDF sits in an awkward middle ground: light enough but moisture-vulnerable and typically stuck with printed finishes that photograph better than they look in person.

Engineered lightweight wall panels occupy the sweet spot. At 14–15 kg/m², they’re roughly 20% the weight of a comparable stone installation but heavy enough to feel substantial, with the structural integrity to back it up.

The Material Science of “Engineered” Lightweights

There’s a fundamental distinction the industry often glosses over: the difference between topical finishes and integrally coloured composites.

Topical finishes—think vinyl wraps, printed laminates, even spray-applied coatings—sit on the surface. Scratch them and you expose the substrate beneath. They’re essentially costumes, and they age like costumes: the edges lift, the seams show, the illusion breaks down under the fluorescent lights of a busy reception area.

Integrally coloured composites are different beasts entirely. The aesthetic runs through the material itself—damage a corner and you’ll find the same visual character beneath. This is the approach Stonini takes with their composite: a material matrix where pigment and aggregate are distributed throughout, not applied after the fact.

The tactile result matters more than you might expect. Run your hand across a well-made composite panel and you’ll feel the cool-to-the-touch quality of actual stone. It’s not warm like plastic or hollow like printed board. For a wellness centre reception or a hotel lobby where guests actually touch surfaces, this sensory authenticity counts.

But the real specification advantage is structural. A 20mm stone slab can hit 150 kg/m²—that’s serious weight demanding serious engineering. The same aesthetic achieved in lightweight wall panel composite runs around 14–15 kg/m², roughly 20% of that load. This weight allows installation directly onto standard 12mm MDF backing or even direct-to-stud in appropriate applications, eliminating the expensive structural engineering reports that accompany every real stone commercial project.

Ask any architect who’s had to value-engineer a stone lobby down to painted plasterboard, and they’ll tell you: this weight difference isn’t marginal. It’s often the difference between delivering the design intent and abandoning it entirely.

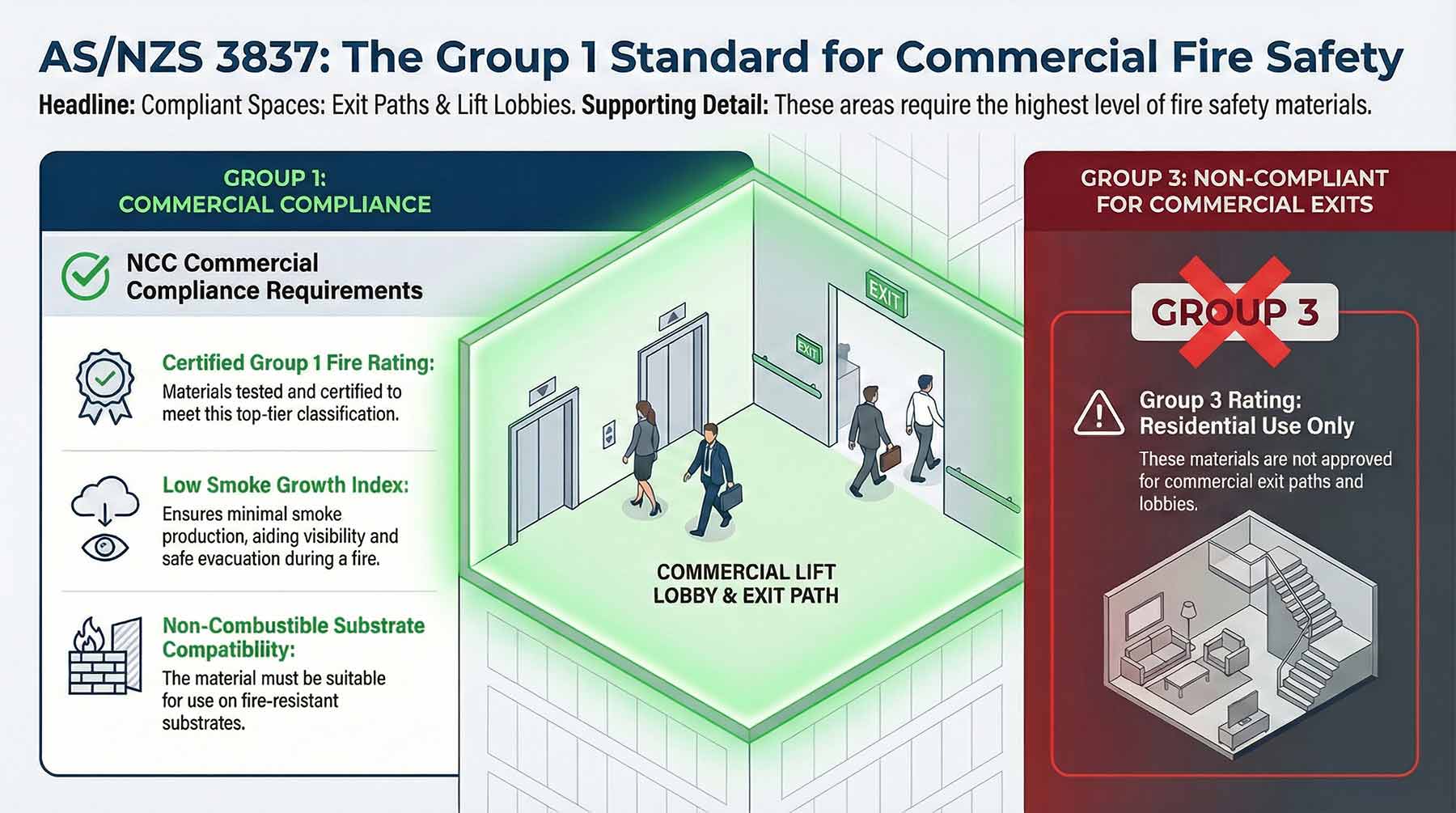

Fire Safety and NCC Compliance (The Dealbreaker)

Here’s where specification gets serious, and where a lot of imported “lightweight” panels quietly fail.

The National Construction Code requires Group 1 fire performance for wall linings in exit paths, lobbies, and other critical areas within Class 2–9 buildings. Many imported panels—particularly the cheaper polymer options flooding the market—simply don’t meet this threshold. Some arrive with overseas certifications that don’t translate to Australian standards. Others claim compliance based on testing methods that differ from AS/NZS 3837.

The consequences of getting this wrong aren’t just regulatory. Fire-related litigation cuts through limitation periods and directors’ insurance like nothing else in construction. A building certifier who signs off on non-compliant materials carries personal liability. No one wants to be explaining their panel selection to a coronial inquiry.

Lightweight Stonini panels are tested and certified to AS/NZS 3837 Group 1, making them what the industry calls a “safe spec” for commercial applications. This isn’t marketing language—it’s the practical reality of specifying materials that building certifiers will accept without lengthy technical justification.

Large Format Capability: Reducing Site Complexity

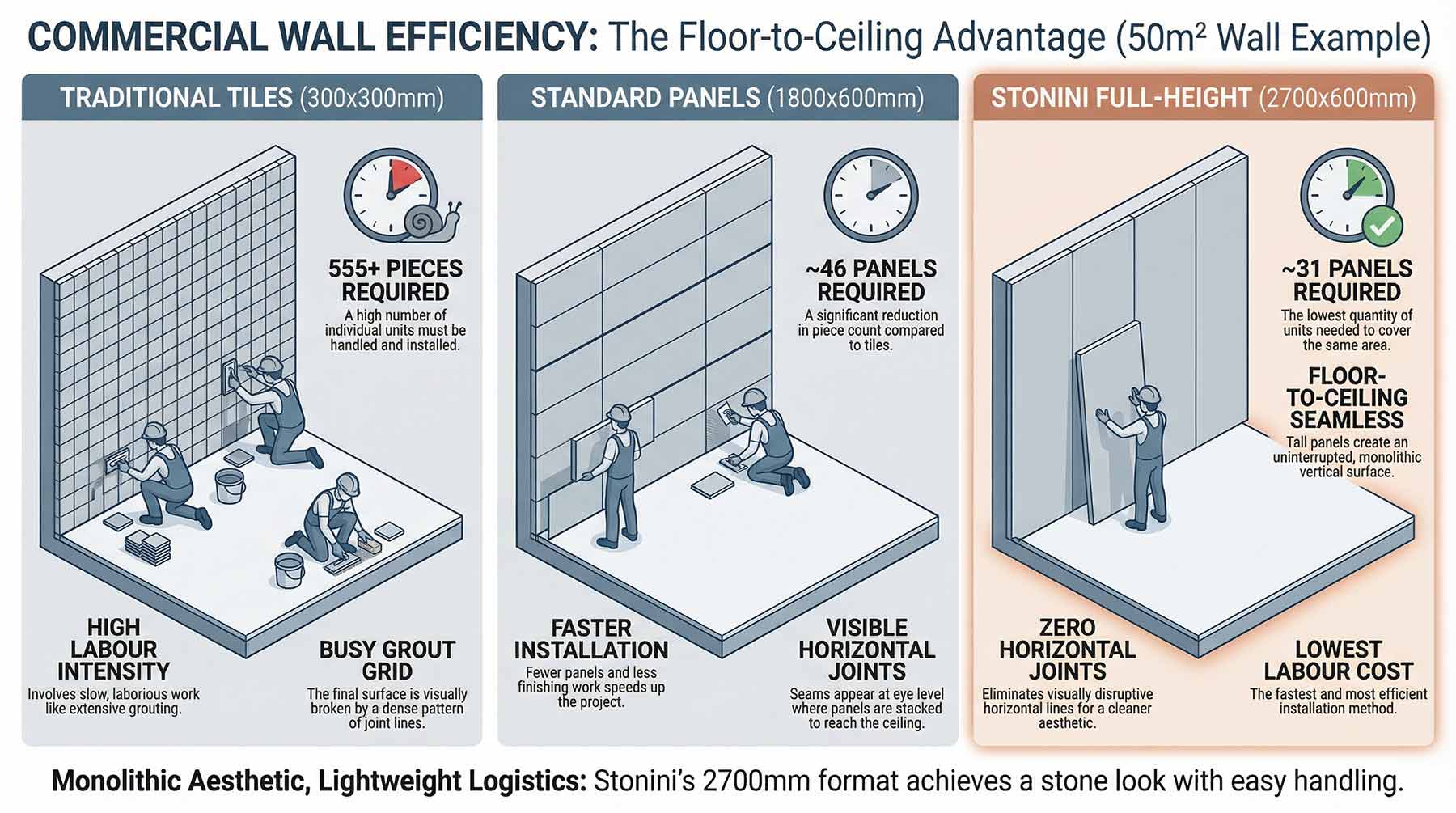

Large format panels — Stonini produces them up to 2700mm x 600mm—aren’t just an aesthetic choice. For commercial interiors, they’re a logistical decision with direct cost implications.

That 2700mm dimension is deliberate. Installed vertically, these panels run floor-to-ceiling in standard commercial fitouts without a single horizontal joint. No mid-wall seam breaking the visual plane. No grout line at eye height catching dust and drawing attention. Just uninterrupted surface from skirting to ceiling—the kind of seamless finish that typically requires poured concrete or full-height stone slabs at three times the cost and ten times the structural headache.

And here’s what makes it practical: even at that impressive 2700 x 600mm size, each panel weighs only around 20kg. Two installers can handle them comfortably without mechanical lifting equipment. Compare that to a natural stone slab of equivalent dimensions—you’d be looking at 80–120kg minimum, requiring suction lifters, additional labour, and careful coordination to avoid damaging the material or the installers.

Consider the mathematics of a 50-square-metre feature wall. In traditional 300 x 300mm stone tiles, that’s roughly 555 individual pieces requiring placement, levelling, grouting, and cleaning. In 1800 x 600mm panels, you’re looking at approximately 46 panels. Go full-height with 2700 x 600mm formats and that drops further still—around 31 panels with vertical joints only. Fewer joints means faster installation, reduced labour hours, and less opportunity for site-induced variation in the finished result.

The grout factor matters aesthetically too. Every joint is a potential failure point—a place where moisture can penetrate, where differential movement can crack grout, where cleaning becomes tedious. Larger formats minimise these vulnerabilities while creating the seamless visual planes that contemporary commercial design demands.

Where hand-cast lightweight wall panels like Stonini’s Concrete and Delta (marble) ranges excel over machine-made alternatives is in concealing what joints remain. Machine-made panels have uniform, repeating edges—line up four of them and you see the grid. Hand-cast panels have subtle edge variation that allows skilled installers to blend horizontal seams, achieving a continuity that looks genuinely monolithic rather than obviously modular.

This isn’t theoretical. Walk through any premium hotel lobby with large-format stone-effect walls and you’ll notice—or rather, you won’t notice—the join lines. That invisibility is the point. It’s the difference between a feature wall that reads as architecture and one that reads as cladding.

Aesthetic Versatility of Lightweight Wall Panels: From Earth to Industrial

Rather than walking through a product catalogue, it’s more useful to think about design palettes—the aesthetic territories these materials can credibly occupy.

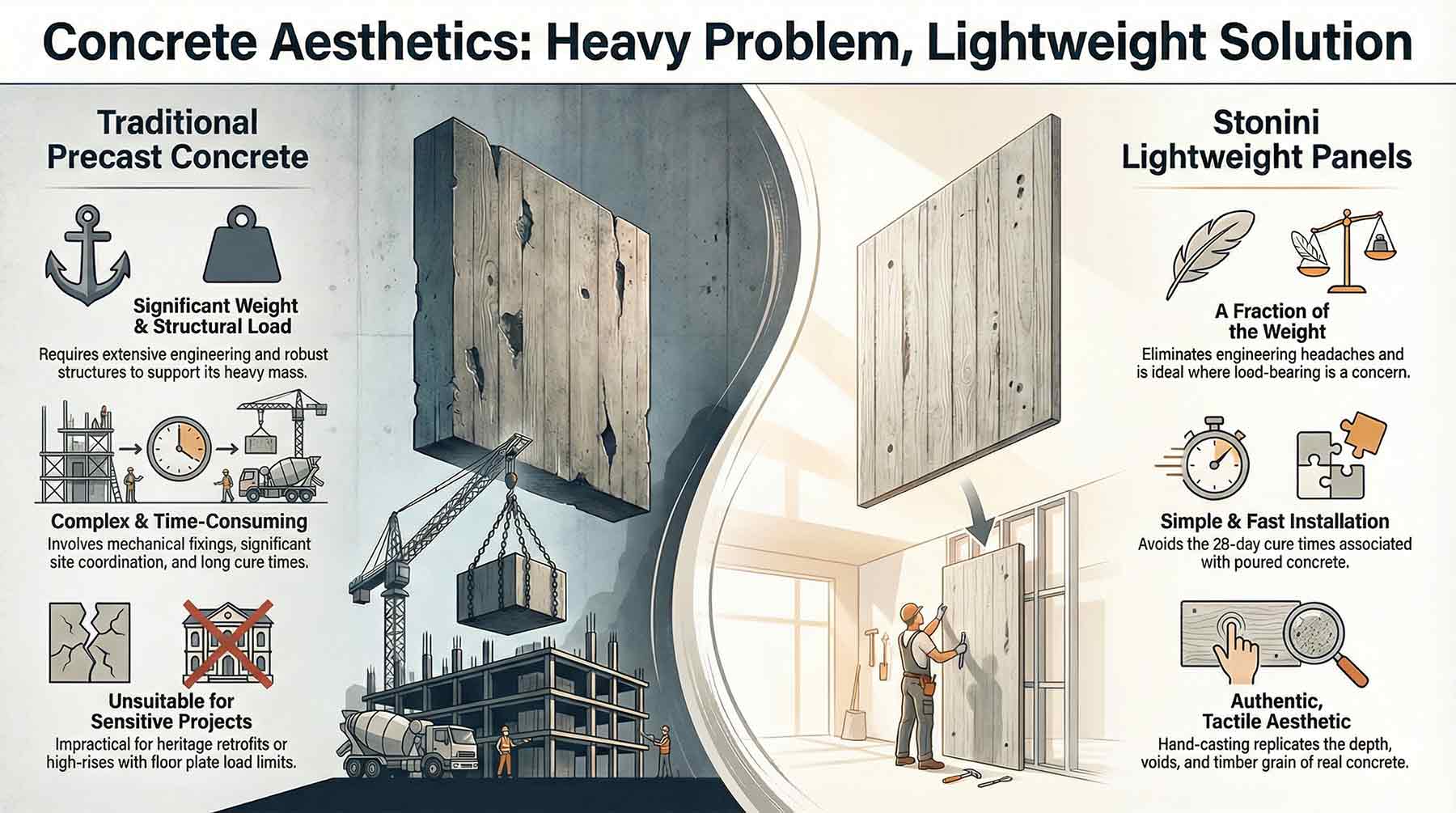

The Faux Concrete Aesthetic

The board-formed concrete look—raw, pitted, showing the grain of formwork timber—has become near-universal in contemporary commercial design. Law firm lobbies, creative agency receptions, high-end retail: the language of honest materiality speaks across sectors.

Achieving this traditionally requires either poured in-situ concrete (expensive, time-consuming, structural) or precast panels (still heavy, requiring mechanical fixings and significant coordination). For retrofit applications or lightweight construction, neither option is realistic.

The Stonini Concrete Effects range replicates this aesthetic at a fraction of the weight and lead time. The hand-casting process captures the tactile depth of real board-formed concrete—the subtle undulations, the air voids, the timber grain impression—without the 28-day cure times or the engineering headaches.

For a high-rise lobby where the lift shaft can’t support additional load, or a heritage retrofit where floor plates won’t tolerate point loading, this becomes the only sensible path to the desired aesthetic.

The Biophilic Earth Palette

Wellness centres, hospitality venues, yoga studios, organic food retailers—an entire sector of commercial design now gravitates toward earth-toned, organic textures. Rammed earth is the hero material here: those stratified, sedimentary layers speaking to geological time and handcraft.

Traditional rammed earth construction is genuinely beautiful but genuinely difficult in commercial interiors. The walls need to be structural. The moisture content needs careful management. The colour consistency depends on soil batch. And good luck getting it past hygiene requirements in a food-service environment.

The Stonini Earth Range offers rammed-earth textures in a format that’s waterproof, mould-resistant, and wipeable—the hygiene credentials hospitality and wellness spaces actually need. At 1850 x 750mm, each panel covers generous surface area while weighing just 17kg. That’s light enough for a single installer to position, yet substantial enough to feel like real earth construction rather than flimsy imitation. The organic aesthetic doesn’t have to compromise on durability or maintenance practicality.

This matters commercially. A day spa wants to evoke natural materiality, but it also needs surfaces that cleaners can sanitise between clients. That dual requirement eliminates most authentic earth-building techniques from consideration. Lightweight wall panels like the Earth Range bridge the gap—delivering the visual warmth of rammed earth without the structural demands or maintenance headaches.

The Specification Reality

For 90% of commercial interior applications, genuine stone and concrete aren’t realistic choices. The weight demands structural accommodation. The lead times stretch programs. The costs blow contingencies. These aren’t criticisms of natural materials—they’re acknowledgments of commercial construction realities.

Lightweight decorative panels exist precisely to fill this gap: delivering material authenticity at weights and costs that commercial projects can actually accommodate. Not a budget compromise, but a specification solution.

The question isn’t whether panels can match real stone—they can’t, and shouldn’t try to. The question is whether they deliver sufficient aesthetic integrity for the application at hand while meeting the fire, moisture, durability, and cost requirements that commercial specification demands. For decorative feature walls, reception areas, lift lobbies, and hospitality environments, the answer is increasingly clear.

Experience the Difference

Specification decisions shouldn’t rely on screen images or catalogue descriptions. Request physical samples from lightweight Stonini panels to assess texture, weight, and visual depth firsthand. Hold the material. Feel the cool surface. Judge the hand-cast authenticity against your project requirements.

Request samples or contact Stonini’s specification team to discuss technical requirements for your commercial project.